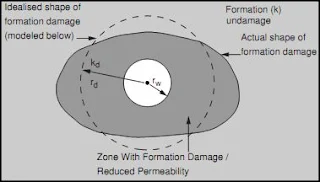

This chapter, entitled “Acidising and other Matrix Treatments”, discusses the chemical methods of well stimulation. The common factor among these treatments is that they are carried out under matrix conditions i.e. the injected fluids flow radially away from the wellbore since the treatment fluid is injected into the well at rates and pressures below that required for creation of a hydraulic fracture. This chapter mainly concentrates on the injection of acid (“Acidising”), the most frequently employed of the chemical treatments.

Matrix (stimulation) treatments are a common form of well intervention aimed at removing this formation damage and restoring the well to its natural, undamaged inflow performance. An alternative stimulation technique - propped hydraulic fracturing - will be covered in a later chapter. This latter well treatment can bypass this damage and/or increase the effective wellbore radius. Either of these stimulation treatments may be carried out immediately after drilling the well is completed or at any time in the well’s producing lifetime when they can be economically justified. Matrix stimulation treatments increase well productivity by pumping a specially formulated treatment fluid (frequently, but not always, an acid) which is designed to remove (normally dissolve) the formation damage. However, the keys to successful treatments are:

1) The identification of a suitable candidate well which is capable of a greater hydrocarbon production rate.

2) The selection of the optimum type of treatment fluid for the removal of the formation damage.

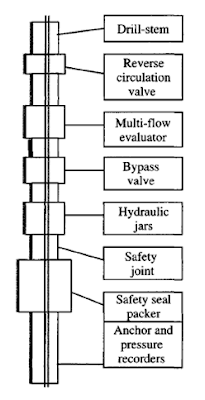

3) The design of the operational aspects of the treatment.

5/31/2011 06:04:00 PM

5/31/2011 06:04:00 PM

Victor Manik

Victor Manik

Posted in:

Posted in: